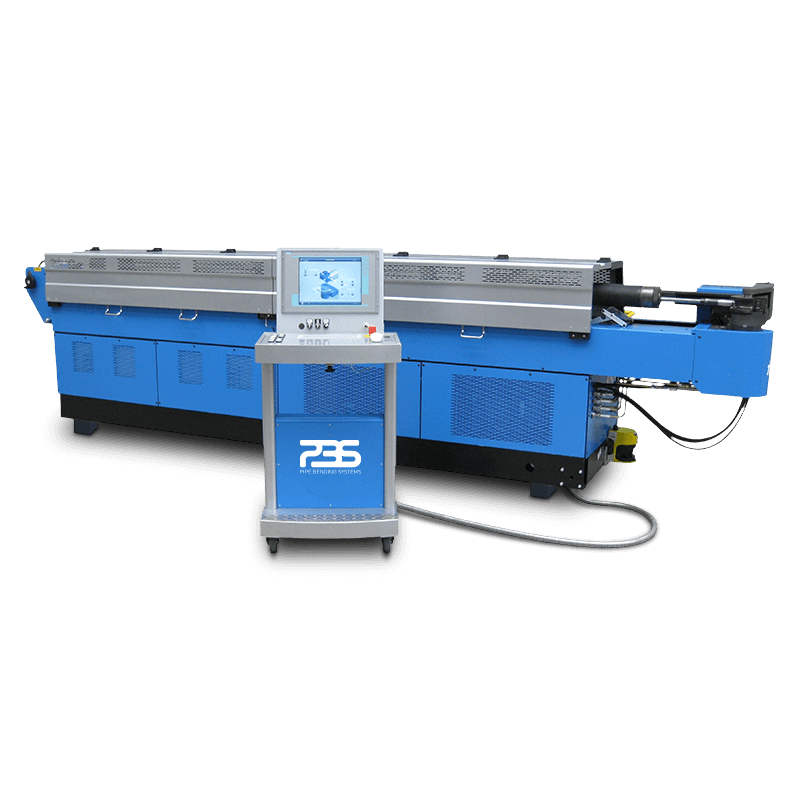

TUBOTRON 50 CNC pipe bending machine

TUBOTRON 50 CNC pipe bending machine

Fully automatic and flexible!

The CNC pipe bending machines of the TUBOTRON series fulfill the highest quality demands regarding design, performance and fabrication. They are perfectly suited for series production as well as for flexible single production of pipe bending parts.

Insight TUBOTRON 50 CNC pipe bending machine

Discover the

TUBOTRON pipe bending machine

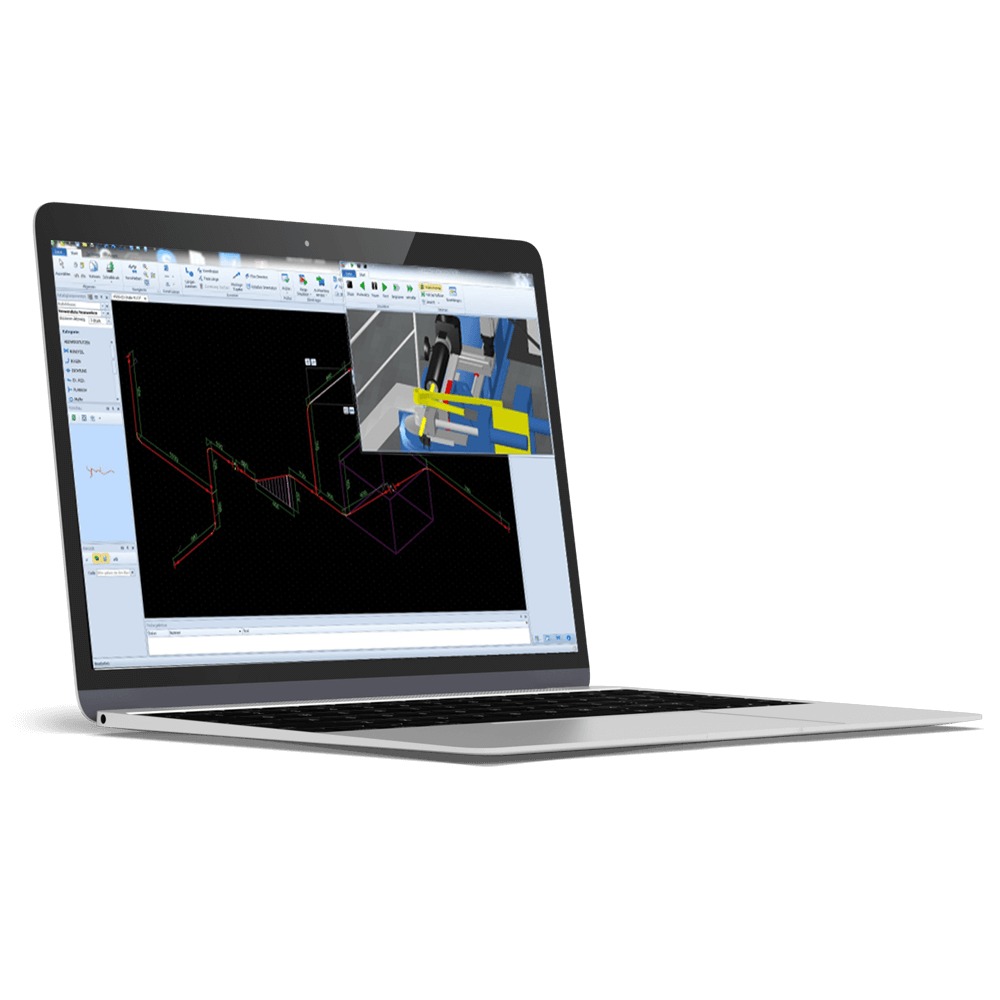

By using the most advanced control techniques even complex pipe shapes can be bent at minimum cycle times and highest precision. The bending machines are operated via SIMATIC Panel PC or SIMATIC Operator Panel. An interface for remote maintenance of the machine control is standard.

TUBOTRON pipe bending machine

The advantages

Increased flexibility

Growing system

Risk reduction

Cost reduction

TUBOTRON 50 CNC in numbers

Technical data

Maximum bending performance (steel pipe)

Ø 50,0 x 5,0 mm

Maximum bending radius

200 mm

Maximum bending speed

43 °/s

Bending accuracy

±0,05 mm / ±0,05 °

Dimensions, approximately (WxHxD)

5100 x 900 x 1200 mm

Usable lengths, approx.

3000/4500/6000 mm

Weight, approximately

2200 kg

Connected load

15,0 kW

- Exposed bending head for maximum bending space

- Programmable sequence control with menu-driven user guidance via SIMATIC Operator Panel

or Touch PC on mobile control board - Hydraulic bending drive

- Hydraulic pipe clamping (power programmable)

- Hydraulic pressure die positioning

- Follower-type pressure die (linear guiding)

- Servo-electric pipe feed and rotation

- Hydraulic long-neck collet chuck allows for positioning of the pipe in the pressure die area,

with pipe re-gripping functionality - Foot switch for hydraulic collet chuck

- Hydraulic and anticipated mandrel retraction

- Automatic minimum quantity mandrel lubrication

- Pipe and mandrel support

- Interface for remote maintenance of the machine control

- Oil cooler

- Pressure die assist (power programmable)

- Anti-buckling system for the mandrel rod

- PIPEFAB BE pipe bending software

- TUBOTRON 50 PLC / TUBOTRON 50 CNC (with servo technology)

- Pipe length (over mandrel): 3000 mm / 4500 mm / 6000 mm

Sylvia Ludwig

Vertrieb / Auftragsabwicklung

If you have any questions, please do not hesitate to contact me.

+49 2725 9540 – 0