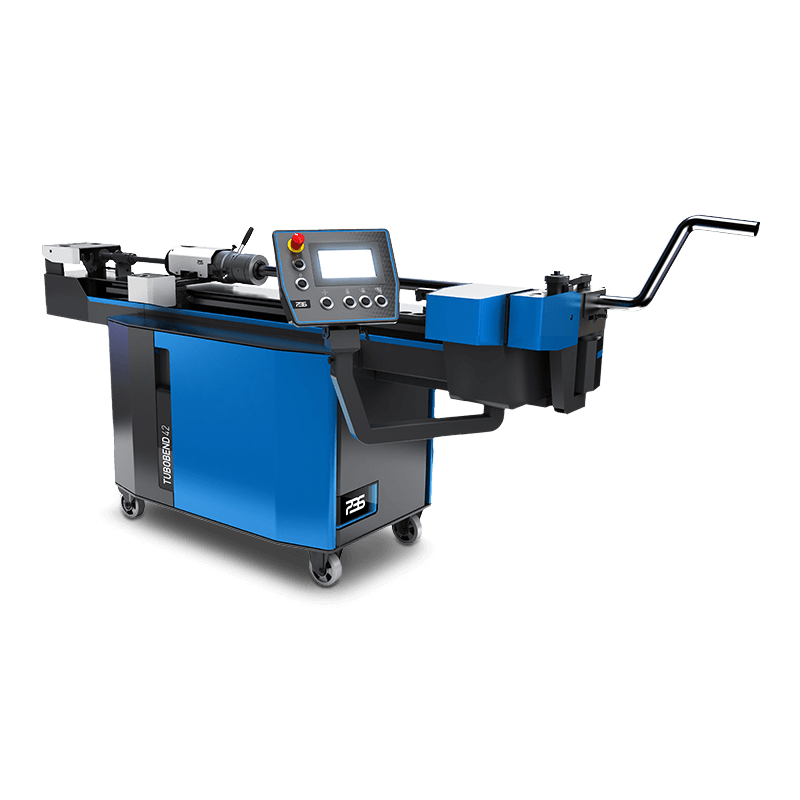

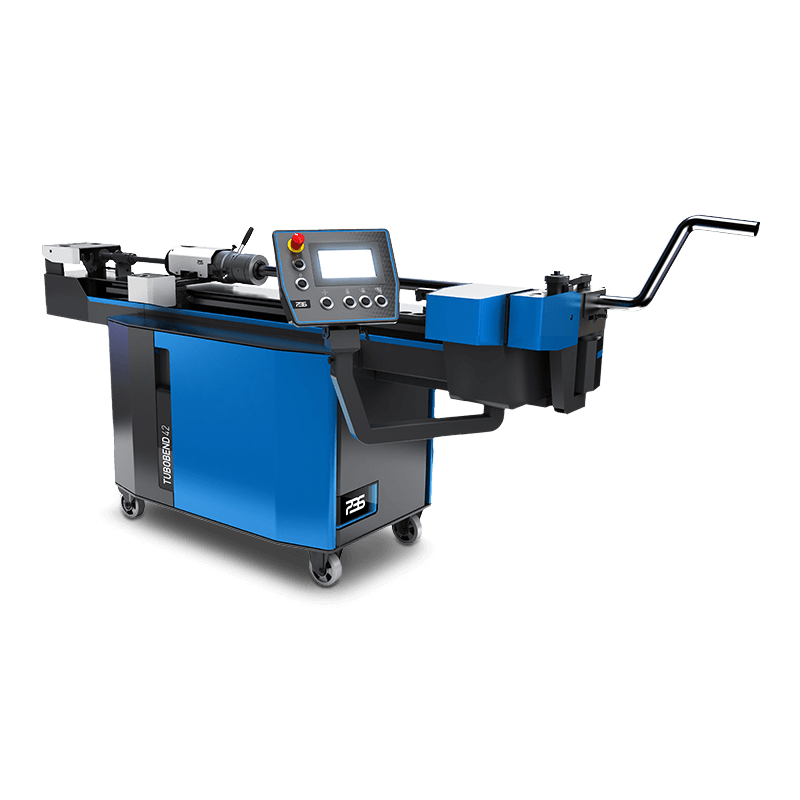

TUBOBEND 42 pipe bending machine

TUBOBEND 42 pipe bending machine

TUBOBEND -

pipe bending

made easy

pipe bending

made easy

The bending axis of the semi-automatic TUBOBEND pipe bending machines is automated, whereas pipe feeding and slewing between two bows have to be executed manually.

Insight TUBOBEND 42 pipe bending machine

Discoverthe new TUBOBEND generation!

The machines are mainly used in the individual and small series production of tube bending parts, for adaptation and maintenance work or as mobile assembly machines (e.g. on construction sites). stoppers for the length and ro-tation positions facilitate the work in the production of small series, since the tube can be precisely fixed on the respective starting posi-tion for the next bend.

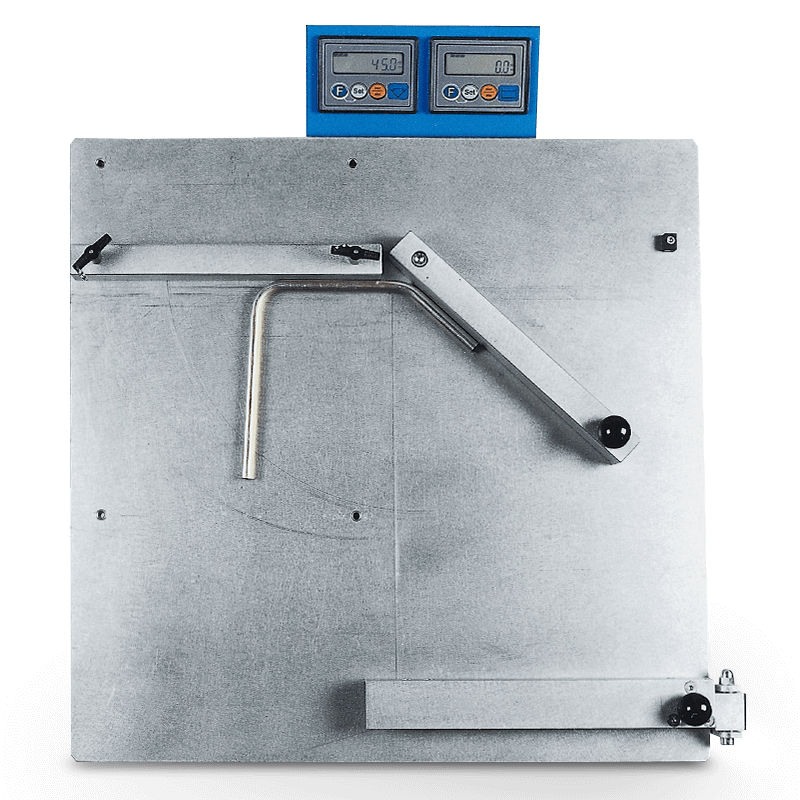

A 2‑axis measuring system with digital display of the current position values for the feed and rotation axis as well as many other features are optionally available.

TUBOBEND pipe bending machine

The advantages

Increased flexibility

Growing system

Risk reduction

Cost reduction

TUBOBEND 42 in numbers

Technical data

Maximum bending performance (steel pipe)

Ø 42,0 x 3,0 mm

Maximum bending radius

125 mm

Maximum bending speed

44 °/s

Bending accuracy

± 0,1°

Dimensions, approximately (WxHxD)

2750 x 1000 x 1250 mm

Usable lengths, approx.

1500/3000/4500/6000 mm

Weight, approximately

770 kg

Connected load

3,25 kW

- Compact and exposed bending head for maximum bending space

- Electronic SIMATIC control for the bending axis with 7″ Touch Panel, set-point / actual value display, automatic sequencing of the data records and storage capability for 100 bending programs

- Ergonomically optimized control panel

- Hydraulic bending drive

- Hydraulic pipe clamping with adjustable clamping pressure

- Hydraulic pressure die positioning

- Hydraulic mandrel retraction

- Optimized tooling concept with very short tool changeover times

- Maintenance-friendly housing concept with optimized accessibilities

- Modern industrial design

- Machine mobile and flexible to use

- Positioning device for pipe length and rotation, incl. 3‑jaw chuck, stoppers and comfortable transversal adjustment

- Mechanical collet chuck or hydraulic collet chuck

- Adjustable bending speed

- Follower-type pressure die (linear guidance), with automatic retraction

- Length and rotation measuring system with digital display

- Braking system for length and rotational positioning of the pipe

- Anticipated mandrel retraction for optimized bend quality

- Mandrel lubrication device

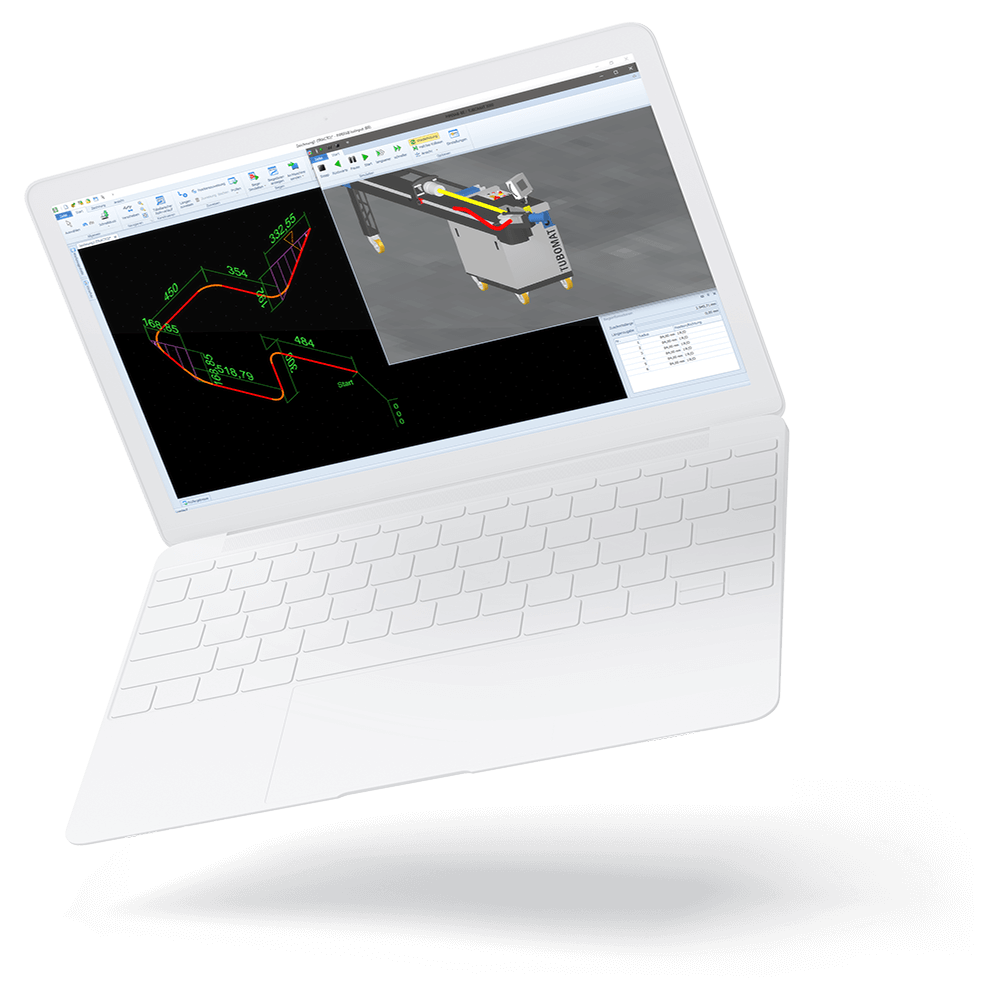

- Interface for data import from PIPEFAB BE pipe bending software

- Interface for remote maintenance of the machine control via VPN

- Machine optionally available as right-hand or left-hand bender

Frank Dobbener

International Sales Manager

If you have any questions, please do not hesitate to contact me!

+49 2725 9540–41+49 170 7988607